What is

RL Core Technologies?

We are a Deeptech company bringing real-time autonomous optimization to industrial control and automation with the power of reinforcement learning.

Industries & Use cases

RL Tune is the intelligence layer that democratizes optimization and makes Real-Time Autonomous Optimization (RTAO) the new default for industrial control.

Chemical & Process Industries

Chemical & Process Industries

- Reactor temperature/feed control

- Distillation column optimization

- Continuous process stabilization

Advanced Industrial Optimization

Advanced Industrial Optimization

- Real-time autonomous optimization (RTAO)

- PID/MPC enhancement

- Adaptive setpoint tuning

- Multi-variable process optimization

- Drift detection and compensation

Data centers

Data centers

- Onsite battery/energy optimization

- Water cooling

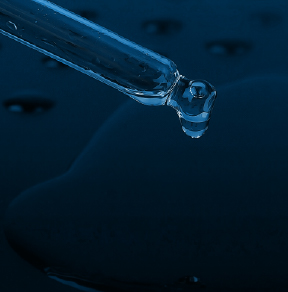

Municipal Drinking Water and Wastewater

Municipal Drinking Water and Wastewater

- Coagulation & Flocculation

- Disinfection

- Aeration & Biological Reduction

- Nutrient Removals

- Pumping & Level Management

Industrial water and Process water

Industrial water and Process water

- Effluent treatment optimization

- Reagent and chemical dosing control

- Aeration and energy reduction

- Thickener and flotation optimization

- Chemical, Oil & Gas

- Food & Bev

- Pulp & Paper

- Mining

Energy Systems & Microgrids (Solar + Bess)

Energy Systems & Microgrids (Solar + Bess)

- Battery charge/discharge optimization

- Peak shaving /cost minimization

- Arbitrage/time-of-use optimization

- Microgrid stability and scheduling

Chemical & Process Industries

Chemical & Process Industries

- Reactor temperature/feed control

- Distillation column optimization

- Continuous process stabilization

Advanced Industrial Optimization

Advanced Industrial Optimization

- Real-time autonomous optimization (RTAO)

- PID/MPC enhancement

- Adaptive setpoint tuning

- Multi-variable process optimization

- Drift detection and compensation

Data centers

Data centers

- Onsite battery/energy optimization

- Water cooling

Municipal Drinking Water and Wastewater

Municipal Drinking Water and Wastewater

- Coagulation & Flocculation

- Disinfection

- Aeration & Biological Reduction

- Nutrient Removals

- Pumping & Level Management

Industrial water and Process water

Industrial water and Process water

- Effluent treatment optimization

- Reagent and chemical dosing control

- Aeration and energy reduction

- Thickener and flotation optimization

- Chemical, Oil & Gas

- Food & Bev

- Pulp & Paper

- Mining

Energy Systems & Microgrids (Solar + Bess)

Energy Systems & Microgrids (Solar + Bess)

- Battery charge/discharge optimization

- Peak shaving /cost minimization

- Arbitrage/time-of-use optimization

- Microgrid stability and scheduling

Results Achieved

13 percent

13% coagulant reduction leading to an efficient ultrafiltration system at Drayton Valley drinking water treatment plant

14.6 percent

14.6% backwash reduction in coagulant dosing & backwash optimization for ultrafiltration, leading to improved scrubber efficiency at EPCOR in less than 12 months.

47 percent

47% scrubber chemical reduction, reducing chemical costs at EPCOR in less than 12 months.

" Partnering with RL Core has been a game-changer for EPCOR. With the Scrubber Optimization Agent in place, we’re saving on chemical costs while simultaneously improving environmental outcomes and operational resilience. The RLCore agent has improved responsiveness, precision, and adaptability to load variations. It gives our operators peace of mind, enabling continuous and adaptive process improvement while maintaining transparency and control. RLCore didn’t just deliver a solution—they became a trusted partner in operational excellence. "

Nathaniel Papay

Senior Manager, EPCOR